1.Summary

This system through the man-machine interaction interface and various signal sensors,can real-time reflect the arm angle, height, working amplitude, lifting weight, load and other information of the excavator to the operator,make the operating capacity of the excavator is safe and effective in the range of design parameters. When the excavator operation is close to or beyond the safe range.The host computer will send sound and light alarm to remind the operator to stop the illegal operation,if the operator continues to violate the rules,the host computer will send auto lock signal and stop the arm of the excavator to dangerous direction,so as to avoid the safety accident of excavator and operator effectively.

2. System constitute

The system consist of one hydrualic pressure sensor,three angle sensors,display and host computer intergrated machine,and mounting bracket.

3. Instrument host computer and display instructions

3.1 Instrument display instructions

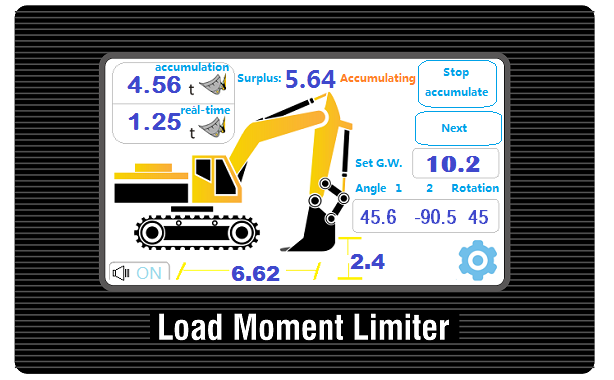

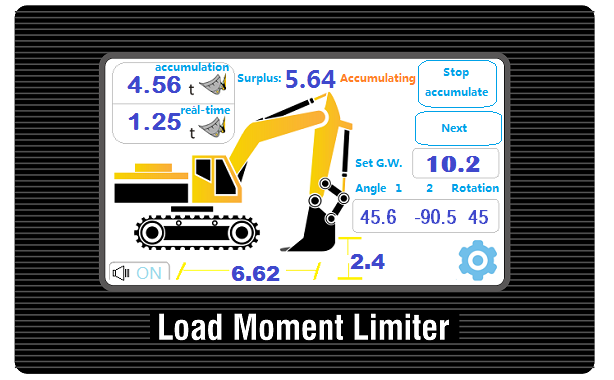

The display is fixed in the proper position in the cab by mounting bracket,adjust the universal joint so that the host computer is in the proper position.After open the machine, the host computer display interface as follows:

⑴The weight of the actual weight of the bucket;

⑵The angle of the the first section arm of excavator which relative to the horizontal line:the above picture show the angle is 12.3°;

⑶The angle of the the second section arm of excavator which relative to the horizontal line(level up to the right):the above picture show the angle is -30.2°;

⑷The angle of the the third section arm of excavator which relative to the horizontal line(level up to the right):the above picture show the third section arm of angle is -60.5°;

⑹Enter setting button

⑺The height of the excavator bucket which relative to the ground:the above picture show the height is 2.5 meters;

⑻The excavator bucket to the central distance:the above picture show the distance between the bucket and the rotary center is 6.6 meters

⑼Mute button;

⑽Load ratio bar;

⑾The rated load of excavator:The above picture show the maximum bearing load of excavator is 30.2 tons;

⑿Load ratio value;The ratio between the actual weight and the rated weight

3.2Host computer wiring instructions

3.3Alarm

1:When detected the weight of the bucket < 90% of the setting rated load,the no buzzer of instrument call,the ratio load bar turn to green;

2:When detected the weight of the bucket > 90% of the setting rated load,the ,the instrument issue sound and light alarm,the horn call intermittently,the ratio load bar turn to yellow;

3:When detected the weight of the bucket > 105% of the setting rated load,the ,the instrument issue sound and light alarm,the instrument issue sound and light alarm,the horm call long,the ratio load bar turn to red;

3.4Stop the buzzer call

In the normal operation of the instrument.touch ,stop the buzzer call,the picture show ;

If want the buzzer return to normal work.touch again;